- Our Products

- Home Page

- Company Profile

- Contact Us

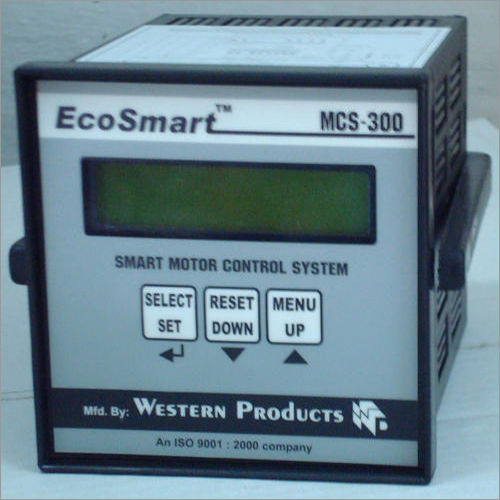

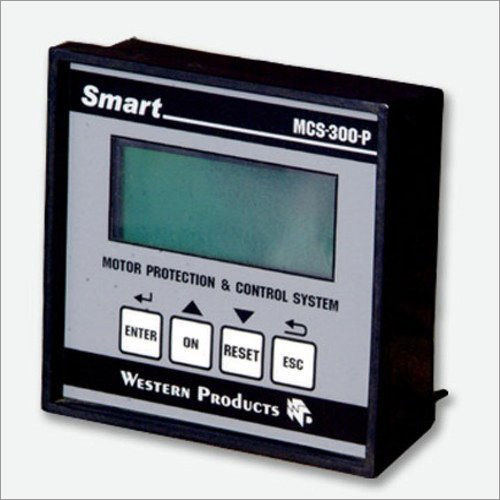

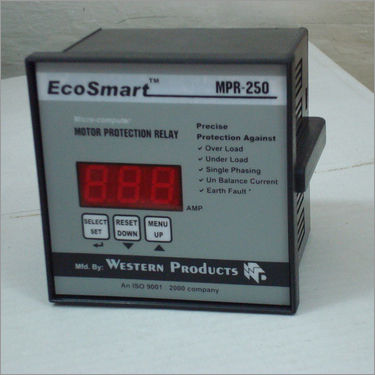

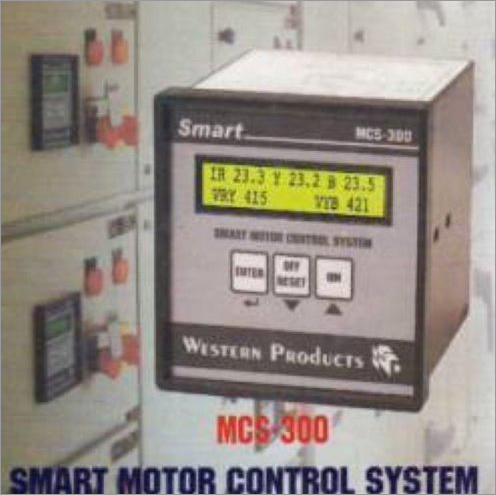

EcoSmart Motor Protection Relays

10500 INR/Piece

Product Details:

- Ambient Temperature -10C to 55C Celsius (oC)

- Dielectiric Strength 2000V AC for 1 min Newtons per Millimetre Squared (N/mm2)

- Coil Power Not Applicable (Solid State)

- Working Temperature -10C to 50C Celsius (oC)

- Protect Feature Overload, Short Circuit, Phase Failure, Phase Sequence

- Power Consumption <2VA Volt-Ampere (VA)

- Contact Form SPDT

- Click to view more

X

EcoSmart Motor Protection Relays Price And Quantity

- 2500.00 - 9000.00 INR/Piece

- 1 Piece

- 10500 INR/Piece

EcoSmart Motor Protection Relays Product Specifications

- 5A @ 230V AC

- Silver Alloy

- 230V AC Ampere (A)

- >100M at 500V DC

- Not Applicable (Solid State) Volt (V)

- >1,000,000 Operations Years

- <50m Volt per ampere (V/A)

- <2VA Volt-Ampere (VA)

- Solid State Relay

- SPDT

- Overload, Short Circuit, Phase Failure, Phase Sequence

- -10C to 50C Celsius (oC)

- <100ms Minutes

- Not Applicable (Solid State)

- Single/Three Phase

- Motor Protection Relay

- For Motor / Feeder / Transformer / Equipment Protection

- -10C to 55C Celsius (oC)

- 2000V AC for 1 min Newtons per Millimetre Squared (N/mm2)

- White & Blue

- Screw Terminal

- 92mm x 55mm x 38mm Millimeter (mm)

- Approx. 150g Grams (g)

EcoSmart Motor Protection Relays Trade Information

- 1000000 Piece Per Year

- 1 Week

- All India

Product Description

Multi Parameter Multi Function Motor Protection Relays which offer complete motor protection, Annunciation & detail analysis with trip time status of various faults like Over Load, Single Phasing, Over Current, Under Current Or Dry Run, Locked Rotor, Un-balance Current, High Voltage, Low Voltage, Earth Fault.

Optional features like RS-232, RS-485, Modbus connectivity also available upon request.

Advanced Motor Protection Technology

The EcoSmart Motor Protection Relay boasts a solid-state design, offering high accuracy and speed with response times of less than 100 ms. Designed for industrial automation, it ensures consistent operation even in demanding environments, supporting a wide range of protective features including overload, short circuit, and phase-related issues.

User-Friendly Operation and Indication

Equipped with clear LED indicators for power (ON) and trip (Fault) status, the EcoSmart Relay enables quick visual diagnostics. Adjustable hysteresis and selectable manual/automatic reset allow customization based on your application needs, providing both flexibility and reliability for maintenance teams.

Robust and Compact Construction

With an IP20-rated enclosure, compact 92 x 55 x 38 mm size, and easy DIN rail mounting, installation is straightforward. The high insulation resistance and mechanical life exceeding 1,000,000 operations guarantee long-lasting and safe performance, helping safeguard critical equipment in harsh industrial settings.

FAQs of EcoSmart Motor Protection Relays:

Q: How is the EcoSmart Motor Protection Relay installed in an industrial setup?

A: The relay is designed for DIN rail mounting, making it quick and easy to install within standard control panels. Screw terminals ensure secure electrical connections, supporting both single and three-phase systems.Q: What types of electrical equipment can this relay be used to protect?

A: EcoSmart Motor Protection Relays are suitable for safeguarding motors, feeders, transformers, and other essential industrial equipment, protecting against issues like overload, short circuit, phase failure, and phase sequence errors.Q: When should you use the manual versus automatic reset function?

A: The manual reset is ideal when you require a deliberate restart after a fault, ensuring safety before recommissioning. The automatic reset option suits processes where downtime must be minimized, allowing the relay to reset itself after conditions return to normal.Q: Where are the LED indicators and what do they display?

A: The relay features LED indicators on its front panel: one shows ON for power status and the other displays TRIP to indicate a detected fault. This enables rapid visual monitoring for operational personnel.Q: What process does the relay follow to protect equipment during faults?

A: Upon detecting a condition like overload or phase failure, the relay disconnects the protected circuit within 100 ms. Adjustable hysteresis and a trip class of 10A ensure precise operation and reduced nuisance tripping, enhancing equipment safety.Q: How is the EcoSmart relay beneficial to industrial operations?

A: By delivering rapid and accurate detection of common electrical faults, the relay minimizes downtime and equipment damage. Its robust construction, longevity, and flexibility in application make it a valuable addition for reliable industrial automation and protection.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Protection Relays' category

"We are accepting only bulk quantity orders."